Silane coupling agent is a commonly used special monomer composed of organic and silane groups. It can play a bonding role at the interface of composite materials, enhancing the compatibility and adhesion between the substrate and filler.

Composite materials are a new type of material composed of two or more different types of materials, with excellent performance and wide application fields. Special monomers play a crucial role in the preparation of composite materials, regulating their properties and functions. The following are some common special monomers for composite material substrates and their functions:

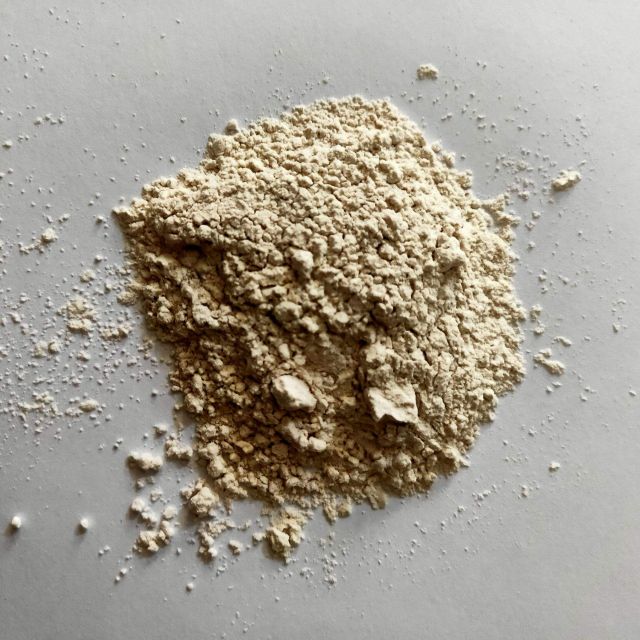

1. Silane coupling agent

Silane coupling agent is a commonly used special monomer composed of organic and silane groups. It can play a bonding role at the interface of composite materials, enhancing the compatibility and adhesion between the substrate and filler. In addition, silane coupling agents can also provide waterproof, wear-resistant, and anti-corrosion properties, and are widely used in composite materials such as plastics, rubber, and fibers.

2. Photosensitive monomer

Photosensitive monomers are a type of special monomers that can initiate polymerization reactions through light, commonly including acrylic acid derivatives and epoxy derivatives. They can undergo rapid polymerization reactions under ultraviolet light irradiation and are used to prepare photo cured composite materials. Photosensitive monomers have the characteristics of rapid curing, high strength, and excellent optical properties, and are widely used in fields such as optical fibers, optical components, and 3D printing.

3. Thermosetting resin monomer

Thermosetting resin monomers are a type of special monomers that can undergo polymerization reactions to form three-dimensional network structures under high temperature conditions. Common thermosetting resin monomers include epoxy resin, phenolic resin, and polyimide. Thermosetting resin monomers have the characteristics of high strength, high temperature resistance, and chemical corrosion resistance, and are widely used in fields such as aerospace, automotive, and electronics.

4. Liquid crystal monomer

Liquid crystal monomers are a type of special monomers with special structures and properties, which can undergo phase transition behavior under electric field or temperature changes. Liquid crystal monomers can regulate the optical, electrical, and mechanical properties of composite materials, and have important application value. For example, in display devices and optical devices, liquid crystal monomers can be used to prepare composite materials with adjustable light transmittance and refractive index.

In summary, special monomers of composite material substrates play an important role in the preparation of composite materials, which can regulate the properties and functions of the materials. Silane coupling agents are used to enhance interface bonding, photosensitive monomers achieve photo curing, thermosetting resin monomers provide high-temperature durability, and liquid crystal monomers regulate optical and electrical properties. With the continuous progress of science and technology, the research and application of special monomers will bring more innovation and development to the field of composite materials.

赞 (0) 赞 (0)

|