Graphite thickening and lubricating dispersants play an important role in industrial production. Its function is not limited to improving lubrication efficiency, but also includes improving the fluidity and stability of materials.

Graphite thickening and lubricating dispersants play an important role in industrial production. Its function is not limited to improving lubrication efficiency, but also includes improving the fluidity and stability of materials. This article will introduce the role of graphite thickener lubricant dispersant and its application in industrial production.

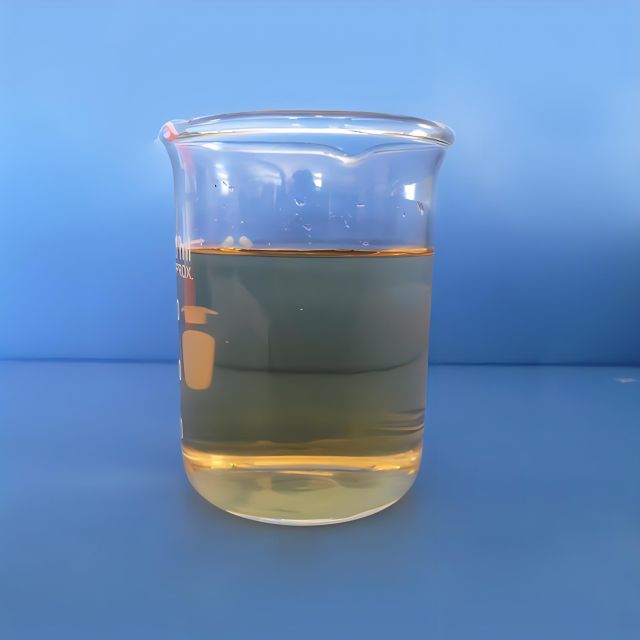

Graphite thickening lubricant dispersant is usually a black powder or lubricant composed of graphite particles. It has the following main functions in industrial production:

1. Thickening effect: Graphite thickening and lubricating dispersants can increase the viscosity of lubricants or lubricating oils, improving their fluidity. Adding graphite thickener to the lubricating liquid can make the lubricant more easily adhere to the surface of the workpiece, forming a uniform lubricating film, thereby improving the lubrication effect.

2. Lubrication effect: Graphite thickening lubricant dispersant itself has good lubrication performance, which can form a protective film on the friction surface, reduce friction coefficient, wear and energy loss. Therefore, in the fields of metal processing, mechanical manufacturing, and bearing lubrication, graphite thickening lubricant dispersants are widely used to improve the surface smoothness of workpieces and extend the service life of equipment.

3. Dispersion effect: Graphite thickening lubricant dispersant can improve the dispersion of graphite particles in lubricants, prevent particle aggregation and precipitation. This helps to maintain the uniformity and stability of the lubricating fluid, avoiding the phenomenon of lubricant layering or agglomeration during use.

4. Thermal conductivity: Graphite thickening lubricant dispersant has good thermal conductivity, which can promote uniform heat transfer of lubricant on the surface of the workpiece, reduce temperature gradient, and prevent thermal deformation and the generation of thermal cracks.

Graphite thickening and lubricating dispersants are widely used in many industries. In metal processing, it can be used in cutting fluids, cooling fluids, and lubricants to improve machining quality and efficiency; In the field of chemical engineering, it can be used in lubricants, greases, and pastes to improve the operational stability and lifespan of equipment; In the electronics industry, it can be used in thermal paste and conductive lubricating grease to improve heat dissipation and electrical contact.

In summary, graphite thickening and lubricating dispersants play an important role in industrial production. They can improve the fluidity, dispersibility, and stability of lubricants, enhance the surface smoothness of workpieces, and extend the service life of equipment. With the continuous development of industrial technology, graphite thickening and lubricating dispersants will also continue to innovate and improve, making greater contributions to the development of industrial production.

赞 (1) 赞 (1)

|