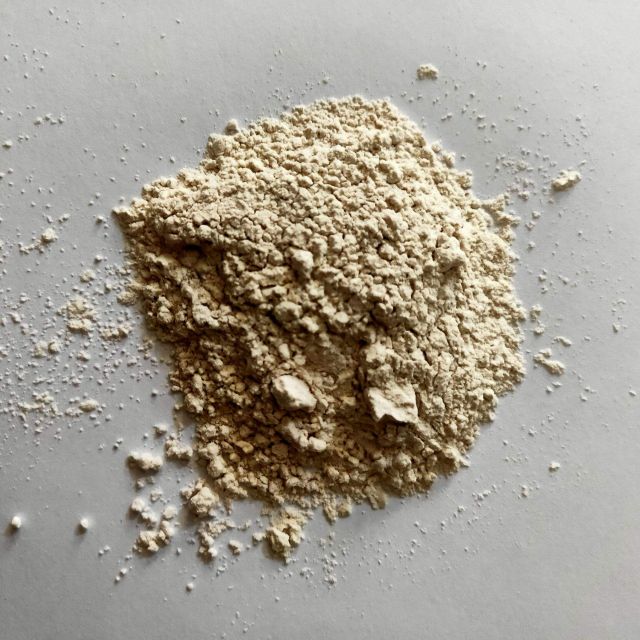

PVP polyvinylpyrrolidone, abbreviated as PVP, is a synthetic polymer compound with extensive application value. It has good water solubility, biocompatibility, and stability, and is widely used in fields such as food, medicine, cosmetics, etc.

PVP polyvinylpyrrolidone, abbreviated as PVP, is a synthetic polymer compound with extensive application value. It has good water solubility, biocompatibility, and stability, and is widely used in fields such as food, medicine, cosmetics, etc. This article will provide a detailed introduction to the production process of PVP polyethylene pyrrolidone.

1、 Raw material selection and pretreatment

1. Raw material selection: The main raw materials in the PVP production process are ethylene pyrrolidone and vinyl acetate. Among them, ethylene pyrrolidone is a key intermediate that needs to be synthesized through chemical methods. Vinyl acetate can be obtained by oxidation of ethylene.

2. Raw material pretreatment: In order to improve the quality and performance of PVP, it is necessary to preprocess the raw materials. Pre processing includes steps such as crushing, mixing, and drying. The specific operation is as follows:

(1) Crushing: Crushing the raw materials separately to facilitate the subsequent reaction process.

(2) Mixing: Mix the crushed ethylene pyrrolidone and vinyl acetate in a certain proportion to form a raw material mixture.

(3) Drying: Dry the raw material mixture at an appropriate temperature to remove moisture and other impurities and improve product quality.

2、 PVP synthesis process

1. Catalytic polymerization reaction of vinyl acetate: Dry vinyl acetate and catalysts (such as copper salts, iron salts, etc.) are added to the reaction vessel in a certain proportion, and polymerization reaction is carried out at a certain temperature and pressure to generate vinyl monomers.

2. Vinyl acetate and vinyl pyrrolidone condensation reaction: The polymerized vinyl monomer is added to the reaction vessel in a certain proportion with unreacted vinyl pyrrolidone, and the condensation reaction is carried out under alkaline conditions to generate PVP products.

3. Solvent extraction and washing: The PVP products in the reactor are extracted using solvents (such as n-hexane) and washed (such as hot water washing) to remove residual catalysts and by-products, resulting in pure PVP products.

4. Drying and packaging: The extracted pure PVP product is dried and then packaged with appropriate packaging materials (such as plastic bags, cardboard boxes, etc.) for transportation and storage.

3、 Quality control and optimization

1. Quality inspection: Strict quality inspection is carried out on key links in the production process (such as raw material selection, pretreatment, synthesis reaction, etc.) to ensure that product quality meets standard requirements.

2. Formula optimization: Based on market demand and product quality requirements, continuously optimize the raw material ratio and production process conditions to improve the performance and yield of PVP products.

3. Equipment improvement: Regularly inspect and maintain production equipment to ensure its normal operation, reduce production costs, and improve production efficiency.

The production process of PVP polyvinylpyrrolidone is a relatively complex process that involves multiple technical points. By strictly controlling key processes such as raw material selection, pretreatment, and synthesis reactions, as well as strengthening quality testing and equipment improvement, the performance and output of PVP products can be effectively improved to meet market demand.

赞 (0) 赞 (0)

|